Get satisfied polymer materials devices in china

Note: Your email information will be kept strictly confidential.

What Do You Want

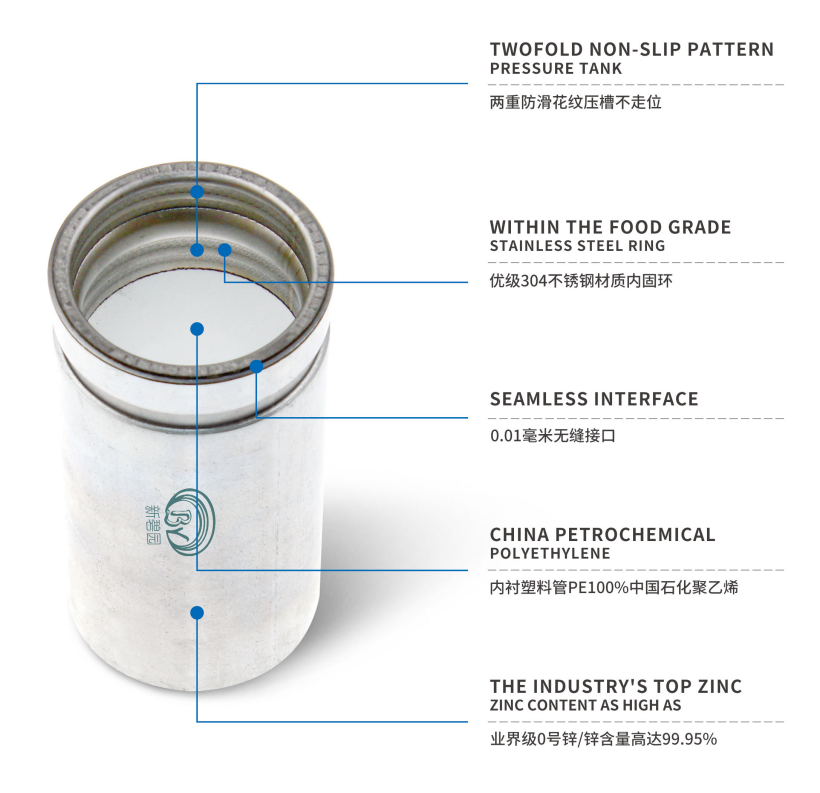

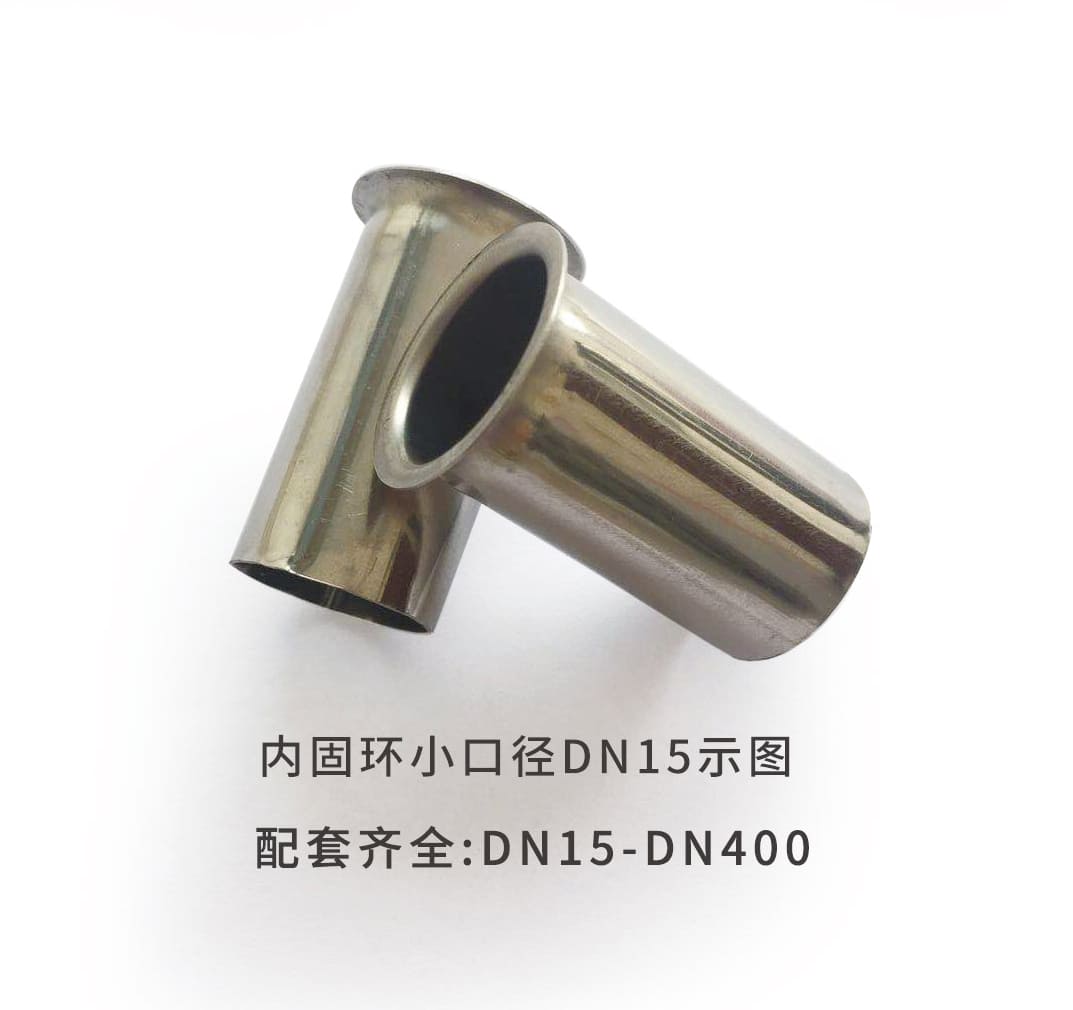

Inner solid ring steel-plastic composite pipe

Product Features:

The steel-plastic composite pipe with inner fixing ring is composed of plastic pipe PE, hot-dip galvanized steel pipe and inner fixing ring, and the steel-plastic composite pipe is installed with the inner fixing ring. Advantages of steel-plastic composite pipe with inner fixing ring

More

INFORMATION

At persent, the known inspecting & controlling in steel pipe embedded plastic pipe , Frequently , degumming and inspecting & controlling outlet tubes or improper operation in the process of construction and damage inside the plastic pipe , plastic pipe shed . So as to accelerate the corrosion of galvanized pipe. Advantages : ♣ Mechanical strength Big Inner solid ring steel-plastic composite pipe and hot-dip galvanized steel pipe have the same excellent mechanical strength, have a strong resistance to impact, bending and pressure, and use pressure range is less than or equal to 1.6MPA. ♣ Anti-corrosion Good The conveying fluid is effectively isolated from the metal body, and it is only in contact with the plastic layer, which has a good corrosion resistance effect and greatly prolongs the service life of the pipeline. ♣ Low fluid resistance The inner wall of the inner solid ring steel-plastic composite pipe is smooth, the friction coefficient is small, the flow rate is fast and does not accumulate scale, and the fluid resistance is small. ♣ High hygienic performance The plastic layer made of edible grade plastic meets the requirements of the national domestic water transmission and distribution standard, GB/T 17219. Solve the following problems: 1. The problem of the plastic tube falling off due to thermal expansion and cold contraction. 2. Avoid the plastic pipe falling off caused by the long-term impact of the water flow on the port nozzle. 3. According to different sizes of steel-plastic composite pipes, set different sizes of pressure grooves. More convenient to install and use. 4. By pressing the groove, the inner fixing ring forms a reinforcing rib inside. Increase the firmness of the inner fixing ring setting. Basic Parameters : wall thickness GROOVE STANDARD DEPTH WIDTH AND ERROR: Deep groove Groove width

Nominal caliber

Nominal outer diameter

Steel pipe wall thickness

Plastic lined pipe

Steel pipe length

mm

in

mm

mm

mm

mm

15

1/2

21.3

2.8

1.5+0.2

6000

20

3/4

26.9

2.8

1.5+0.2

6000

25

1

33.7

3.2

1.5+0.2

6000

32

11/4

42.4

3.5

1.5+0.2

6000

40

11/2

48.3

3.5

1.5+0.2

6000

50

2

60.3

3.8

1.5+0.2

6000

65

21/2

76.1

4.0

1.5+0.2

6000

80

3

88.9

4.0

2.0+0.2

6000

100

4

114.3

4.0

2.0+0.2

6000

125

5

139.7

4.0

2.0+0.2

6000

150

6

165.1

4.5

2.0+0.2

6000

200

8

219.0

6.0

2.5(0,-0.5)

6000

250

10

273.1

7.0

3.0(-0.5,Unlimited)

6000

300

12

323.9

8.0

3.0(-0.5,Unlimited)

6000

350

14

377

8.0

3.0(-0.5,Unlimited)

6000

400

16

426

8.0

3.0(-0.5,Unlimited)

6000

• Pipe diameter

• Error range

65~150

1.9 mm~2.3 mm

9 mm~9.5 mm

+1 mm

200~250

2.4 mm~2.7 mm

11.4 mm~12.4 mm

+1 mm

300

2.6 mm~3.0 mm

11.4 mm~12.4 mm

+1 mm

Related Products

- All

- Adhesive Materials

- For construction board

- Pipe Experts – BI YUAN

- Steel-plastic composite pipe

- Composite Pipe

- Plastic coated composite steel pipe

Market Leading Polymer Materials Solutions Provider

Polymer material provides a rich selection of high-grade material components that can satisfy

your requirements with a short lead-time. Contact our sales team today!

Get satisfied polymer materials devices in china

Note: Your email information will be kept strictly confidential.

PLG RESIN

Company Info